|

|

|

Network Work Shift Timer – NTP Synchronized Bell and Buzzer Controller

Description

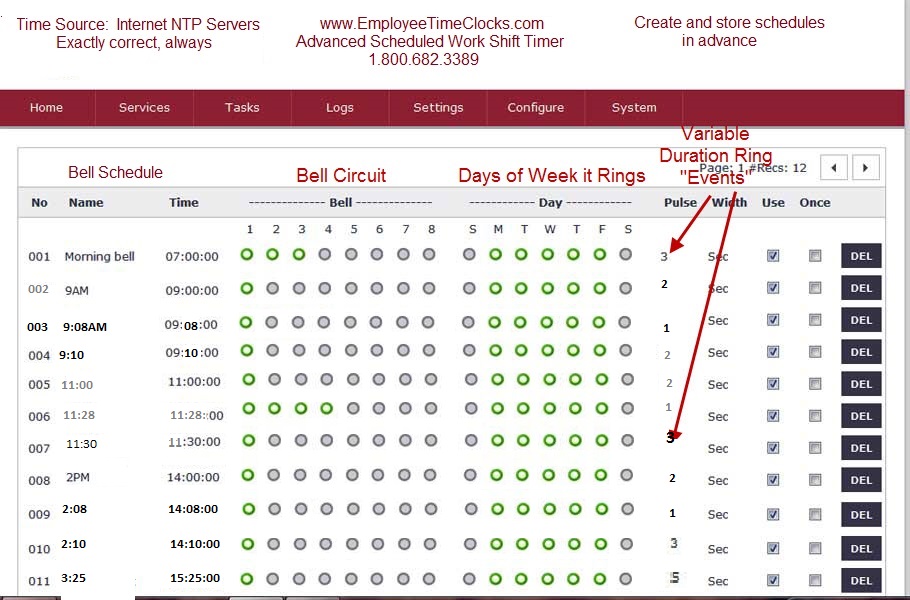

The Network Work Shift Timer is a network-connected controller designed to automate bells, buzzers, or horns using accurate network-synchronized time. It is used to schedule shift changes, breaks, and timed alerts without relying on mechanical timers or manual adjustment. The controller connects to a standard Ethernet network and maintains accurate time through NTP synchronization, allowing consistent signaling across departments.

Scheduling is performed through a web-based interface and stored internally within the controller. Once programmed, the system operates independently and continues running scheduled events without requiring a computer. The unit provides a relay output for activating standard 110VAC signaling devices, making it suitable for both new installations and upgrades to existing bell or buzzer systems. Network synchronization eliminates time drift commonly seen in standalone timers and keeps audible alerts aligned with other network-based systems.

This configuration is typically installed in manufacturing facilities, warehouses, schools, and multi-area environments where consistent timing is required across multiple work areas. The network-based design allows schedules to be adjusted remotely when shift times change while maintaining a single accurate time reference for all signaling events.

Compatibility and Usage

- Ethernet-connected work shift timer with NTP time synchronization

- Relay output for bells, buzzers, or horns

- Schedules stored internally for stand-alone operation

- Compatible with standard 110VAC signaling devices

- Used for shift changes, breaks, and scheduled alerts

- Suitable for replacing mechanical or standalone bell timers

FAQ

Does the timer require a computer to operate?

No. A computer is only used for setup. Once programmed, the controller runs independently.

Why use a network synchronized timer?

Network synchronization prevents time drift and keeps signals aligned with other systems.

Can existing bells or buzzers be used?

Yes. The relay output allows connection to most standard signaling devices.

Related Items

- 6-Inch 110V AC Bell

- Industrial Vibrating Buzzer (110V)

- Manual Ring Button

- Bell Wire (25 ft / 50 ft / 100 ft / 250 ft)

- Surge Protector for Time Clocks

Scheduling work shift timer software for up to two circuits. Use one, or use both.

Set as many times as you want every day (even by the second)

Set up as many schedules as you want, including upcoming schedules and one-time events

Synchronizes with the online atomic clock, via the NTP servers

Click to read about the Linix technology behind our netbell - article one

Click to read about the Linix technology behind our netbell - article two

Linux operating system, housed in the bell/scheduling module

Accessible by Network connection only

Two separate circuits, use one, or use both

Box: Self-contained pvc junction box

Dimensions: 6" x 6" x 4"

Approximate installed weight: 4 lbs

110VAC CAT5 ethernet connection

Made in USA

Works with tone generators.

Designed to be connected to your existing system, or add ours!

Suggested installations:

Connect up to twelve 110VAC bells or seven 4" 110VAC buzzers, per circuit

This is an evolving technology. The core system occasionally gets enhancements.

When you order from us, you will be getting the most current version.

The wiring keeps getting simplified

Our inventory is fresh, it turns over fast. You get the latest version:

In addition to 110VAC, it now supports 24VAC low voltage systems.

Low voltage means you should not have any issues with fire code. No conduit required.

In large installations (100 x 100' and larger), or machine shops, more bells do not make it louder. It makes it easier to hear. Each bell can only go to a maximum of 102DB. Multiple bells are no louder, they are just more easily heard through all the noise.

FYI, when you see car and bike horns (on Facebook, for example) promising 150, even 300DB, know that one, that is a like, and two, that is physically impossible. Google it if you have any doubt.

From ChatGBT:

The loudest sound that can be heard at sea level is theoretically around 194 decibels (dB SPL). Here's why:

Why 194 dB SPL is the limit at sea level:

-

Sound is a variation in air pressure.

-

At 194 dB SPL (Sound Pressure Level), the pressure variation is equal to atmospheric pressure (approximately 101,325 Pascals or 1 atmosphere).

-

Beyond this, sound waves turn into shock waves because the negative pressure part of the wave cannot go below a vacuum.

-

This limit is sometimes called the "sound barrier" for air pressure at sea level.

Real-world examples near that limit:

This system pays for itself.

Example:

You are in manufacturing, you have 10 or more employees.

They drag out break and lunch time by 2 to 3 minutes, every day, two breaks, one lunch a day. Worse yet, you have "smokers"

When the lunch ends, someone has to shout "Back to work!"

Stop the drama, the bell becomes "the bad guy." Not you or a manager.

Install a simple - or advanced - bell or buzzer system, the bell becomes that "bad guy."

They won't miss a break, they will take lunch on time, they will start when they should, they will come back, like trained people, when they are supposed to.

You will collect back, using very conservative numbers, a minimum of 4 minutes per day per person.

Doesn't sound like much, you would be wrong.

Using extremely conservative numbers, the math won't lie:

1 employee, $20 per hour WITH taxes and benefits. (You're realling paying about $14 up front, you can't avoid the taxes, PTO, insurances):

That's 34 cents labor cost, one low-pay employee, per minute.

Recover 1 minute of break time. 2 minutes of lunch time. 1 more minute of second break.

Remember, they then work until the END OF DAY with the bell system, not relaxing 15 minutes ahead of time. That's additional labor expenses you recover..

We can count on 4 minutes absolute minumum time recoverd, per man, per day. 4x.34=$1.36 per day. 5 days: $6.80 per week.

52 weeks: $352 per year per employee in recovered labor time. Every year.

$352 x 10 employees: $3,520. Every year. And the shop becomes more organized.

Add a digital clock so that they all know exactly what time it is, and it gets even better.